Electrolyzed Titanium Coated Tube Electrode

2.Ru-ir oxide Coating,8-12micron;ir-ta oxide coating 8-12micron;platinum coating 0.5-2.5micron.

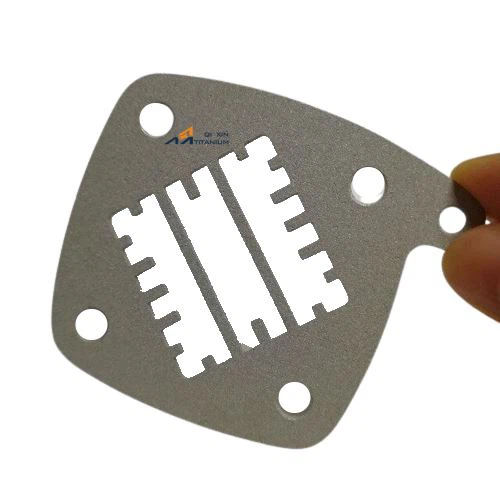

3.Size: Customizable.

4.Surface Treatment: Sand blasting,Acid cleaning, Polished,brushing.

5.production time: 15 working days.

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Electrolyzed Titanium Coated Tube Electrode for Product Introduction

Introduce the Electrolyzed Titanium Coated Tube Electrode as a highly efficient, durable component used in electrochemical applications, providing optimal performance in challenging environments. Emphasize its primary use in processes like water treatment, electroplating, and chemical production, where high efficiency and low maintenance are essential.

- Key Features: Highlight its corrosion resistance, long lifespan, and high conductivity, detailing why these qualities make it indispensable for industrial applications.

Technical Specifications

Provide a detailed table with specific values to allow customers to assess the technical viability for their needs.

| Specification | Details |

|---|---|

| Material Composition | Titanium Grade 1/2, IrO2 coating |

| Dimensions | Customizable: Length (X cm), Diameter (Y mm) |

| Surface Treatment | Anodized with advanced coatings for enhanced conductivity and longevity |

| Current Density Range | X – Y A/cm² |

| Working Voltage Range | Z – W V |

|

|

|

|

|

|

|

|

|

Physical and Chemical Properties

- Corrosion Resistance: Describe the electrode’s resilience against various corrosive agents, making it ideal for harsh environments.

- High Temperature Resistance: Highlight its stability and performance retention under elevated temperatures.

Product Features

Explain how the coated Electrolyzed Titanium Coated Tube Electrode functions within electrolysis, providing benefits such as reduced energy consumption and extended service life.

- Benefits:

- Increased Efficiency: Its excellent conductivity reduces energy loss, maximizing output.

- Longevity: The robust build minimizes replacement frequency, lowering long-term costs.

- Reduced Maintenance: With durable, high-quality coating, it requires minimal upkeep, reducing operational downtime.

Electrolyzed Titanium Coated Tube Electrode Applications

Outline industries and use cases, reinforcing the Electrolyzed Titanium Coated Tube Electrode's versatility.

|

|

|

|

- Industries Served:

- Electroplating

- Desalination and Water Treatment

- Chemical Processing

- Case Studies: Briefly describe examples where Qixin Titanium’s electrodes have significantly improved client operations.

Manufacturing Process

Describe how stringent quality control and advanced manufacturing methods ensure consistent, high-quality Electrolyzed Titanium Coated Tube Electrodes.

- Quality Assurance: Outline the stages of testing from material selection to final inspection.

- Certifications: ISO9001 and other relevant certifications to underscore product reliability.

Company Overview

A brief introduction to Qixin Titanium Co., Ltd., highlighting its two-decade expertise in titanium anode production, dedication to quality, and customer-first approach.

- Mission & Vision: Detail the company’s ongoing commitment to innovation and excellence.

Packaging and Logistics

- Shipping Information: Describe secure, tailored packaging options to protect against environmental factors during transit.

- Delivery Times: Typical lead times and expedited options, ensuring transparency for planning purposes.

Why Choose Us

Reinforce Qixin Titanium’s unique value propositions, emphasizing product reliability, customer support, and industry expertise. Mention positive customer feedback or results from case studies.

Factory Show

|

|

|

Equipment

|

|

|

Production

|

|

|

Testing

|

|

Packaging

|

|

|

Our coated titanium anode are widely used in industries such as electrochemistry, water treatment, and metalplating. They are known for their excellent performance, durability, and efficiency, which helps our customersachieve their production goals and enhance their competitiveness in the market.

Quality is our top priority. We adhere to strict quality control measures throughout the manufacturing process toensure that every anode we produce is of the highest quality. Additionally, we offer customized solutions to meetthe specific needs of our clients, providing them with tailor-made products that perfectly fit their applications.At Oixin titanium Co.Ltd, we are committed to providing exceptional customer service. Our dedicated salesand support teams work closely with customers to understand their reauirements and provide prompt andeffective assistance.Looking to the future, we will continue to invest in research and development to stau at the forefront of the coatedtitanium anode industry. We aim to expand our product range, improve our services, and build long-termpartnerships with customers worldwide.

Our patents and honors

OEM Services

To meet specific project needs, we offer a variety of customization options for titanium alloy rods. Here's an overview of the available customizations:

Material Alterations: We can adjust the composition of the titanium alloy to enhance specific properties. For instance, we can incorporate additional elements such as aluminum, vanadium, or molybdenum to improve strength and heat resistance .

Sizing Adjustments: The length and diameter of the titanium rods can be customized to fit your project requirements. Whether you need rods with specific dimensions or require them to be cut to certain lengths, we can accommodate these needs .↳

Surface Treatments: We provide multiple surface finish options, including polishing, anodizing, and passivation, which can enhance the appearance and corrosion resistance of the rods .

Custom Marking: For identification and tracking purposes, we can engrave or mark the titanium rods with company logos, specifications, or serial numbers .

Custom Packaging: We offer various packaging solutions, such as cardboard boxes, wooden crates, and vacuum thermoforming, along with cushioning materials to ensure safe

FAQs

Include answers to commonly asked questions about Electrolyzed Titanium Coated Tube Electrode, such as:

- What is the lifespan of a titanium coated tube electrode?

- How do I determine the right specifications for my application?

- Can I request custom sizes?

Contact Details

Encourage visitors to get in touch for quotes, more information, or to place an order.

Direct Contact

· Email: info@mmo-anode.com

· Phone: +86 18395477537, +86 13759759535, +86 18991769543, +86 15891475263

· WhatsApp: +86 18395477537, +86 13759759535, +86 18991769543, +86 15891475263

Send Inquiry

You may like