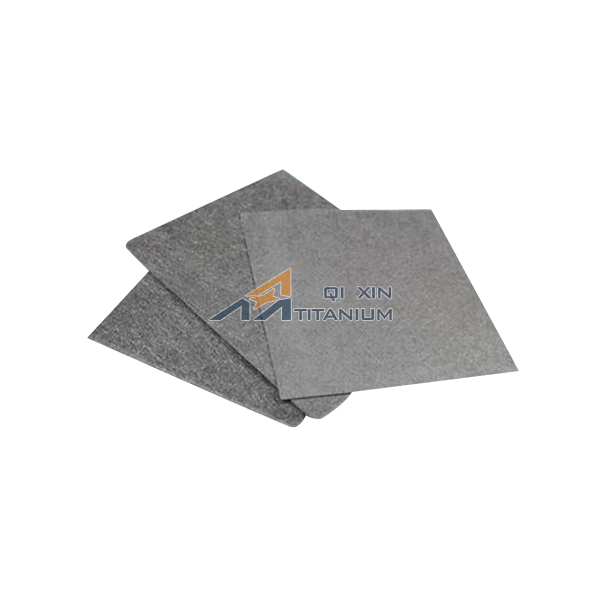

sintered metal fiber felt filter

Filter rate:1-300μm.

Specification:L≤ 1200 mm * W≤ 1000 mm * T(0.2-10mm).

Working temperature:≤ 816 ℃.

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Sintered Metal Fiber Felt Filter Introduction

Introducing our sintered metal fiber felt filter, a cutting-edge filtration solution designed to meet the rigorous demands of various industries. These filters are engineered to withstand extreme conditions, offering exceptional high temperature resistance, corrosion resistance, and structural stability. Whether you're working in high-pressure environments or require reliable filtration in harsh chemical settings, our sintered metal filters are the ideal choice. Their robust design ensures consistent performance, making them essential for applications in petrochemical, pharmaceutical, and food and beverage industries.

Technical Specifications

| Specification | Details |

|---|---|

| Material | Stainless Steel, Titanium, Nickel |

| Pore Size Range | 1 µm to 100 µm |

| Filtration Efficiency | 99.9% (depending on pore size) |

| Operating Temperature | Up to 800°C |

| Operating Pressure | Up to 50 bar |

| Dimensions | Customizable |

Our detailed specifications allow you to quickly find key data, ensuring you choose the right filter for your needs.

|

|

|

|

Sintered Metal Fiber Felt Filter Key Features

- High Porosity: Our sintered metal fiber felt filter feature an intricate structure that provides high porosity, allowing for maximum flow rates while maintaining excellent filtration efficiency.

- Durability: These filters are designed for longevity. Their sintered construction ensures they can withstand significant wear and tear, making them a reliable choice for industrial applications.

- Easy Cleaning and Reuse: Designed for ease of maintenance, these filters can be cleaned and reused, providing cost-effective filtration solutions.

- Exceptional Resistance: With outstanding resistance to high temperatures, corrosive substances, and pressure, our filters are built to perform in the harshest environments.

Sintered Metal Fiber Felt Filter Applications

The products are versatile and can be utilized across a wide range of industries, including:

- Petrochemical: Used for fine filtration and separation of liquids and gases, ensuring product purity.

- Pharmaceutical: Ideal for critical applications requiring stringent filtration standards.

- Food and Beverage: Helps maintain quality and safety by filtering contaminants effectively.

- Gas Filtration: Efficiently removes particulates from gases in various industrial processes.

Their ability to deliver precise filtration makes them invaluable in fine filtration, separation, and purification processes.

|

|

|

|

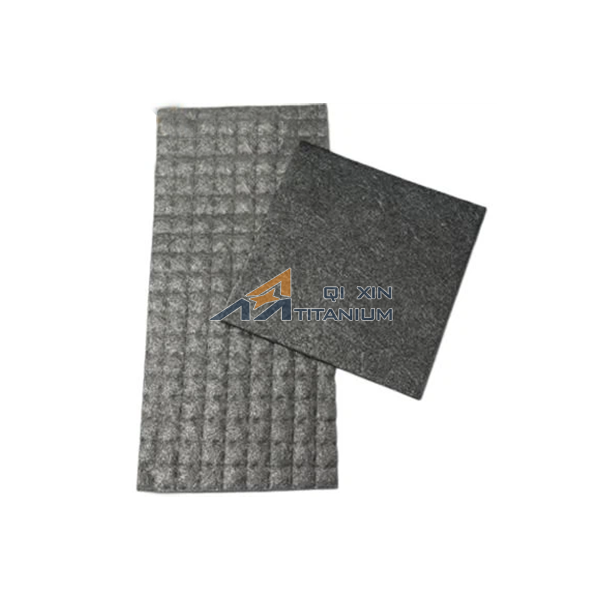

Manufacturing Process

The manufacturing of the products involves a sophisticated sintering and forming process. This method enhances the filters' structural integrity and performance characteristics. The fibers are densely packed and subjected to high temperatures, causing them to bond together, resulting in filters that exhibit high strength and stability.

Key advantages of our process include:

- Multi-layer structures: This provides additional filtration depth and efficiency.

- Special molding techniques: Ensures consistent quality and performance across all products.

Customization Options

We understand that every application is unique. Therefore, we offer customization options to suit your specific requirements, including:

- Size: Tailored dimensions to fit your systems perfectly.

- Aperture: Selection of pore sizes to meet your filtration needs.

- Shape: Custom shapes to integrate seamlessly into existing setups.

- Material: Choice of materials depending on environmental conditions and chemical compatibility.

Our flexible production capabilities enable us to provide solutions that precisely match your needs.

Quality Assurance

At Qixin Titanium Co., Ltd., quality is our top priority. We implement strict quality control processes throughout the manufacturing cycle to guarantee that every sintered metal fiber felt filter meets the highest standards. Our products are certified to relevant quality certifications, including ISO, ensuring you receive reliable and effective filtration solutions. We conduct thorough testing and inspection processes to validate the performance and durability of our filters.

Packaging and Logistics

To ensure your products arrive in perfect condition, we use customized packaging tailored to the unique needs of our sintered metal filters. This packaging protects against damage and environmental factors during transit. Our logistics systems are designed for efficiency, allowing for timely deliveries worldwide. We prioritize your satisfaction and work diligently to ensure that your orders reach you promptly and safely.

Customer Support

We are committed to providing comprehensive pre-sales and after-sales support. Our dedicated teams are here to assist you with any questions or concerns. From product selection to maintenance advice, we ensure you receive the support necessary to maximize your filter's performance.

- Contact Us: Reach out via email at info@mmo-anode.com or call us at +86 9173307518 for immediate assistance.

- After-sales Guarantee: We stand behind our products, offering guarantees to ensure your complete satisfaction.

Why Choose Us

Choosing Baoji Qixin Titanium Co., Ltd. means opting for a company with nearly two decades of industry experience. Our technical expertise, commitment to quality, and innovative manufacturing processes position us as leaders in the coated titanium anode sector. We pride ourselves on our ability to deliver customized solutions that enhance your operational efficiency and competitiveness.

Core Competencies:

- Advanced engineering capabilities

- Robust R&D framework

- State-of-the-art manufacturing facilities

Factory Show

|

|

|

Equipment

|

|

|

Production

|

|

|

Testing

|

|

Packaging

|

|

|

Our coated titanium anode are widely used in industries such as electrochemistry, water treatment, and metalplating. They are known for their excellent performance, durability, and efficiency, which helps our customersachieve their production goals and enhance their competitiveness in the market.

Quality is our top priority. We adhere to strict quality control measures throughout the manufacturing process toensure that every anode we produce is of the highest quality. Additionally, we offer customized solutions to meetthe specific needs of our clients, providing them with tailor-made products that perfectly fit their applications.At Oixin titanium Co.Ltd, we are committed to providing exceptional customer service. Our dedicated salesand support teams work closely with customers to understand their reauirements and provide prompt andeffective assistance.Looking to the future, we will continue to invest in research and development to stau at the forefront of the coatedtitanium anode industry. We aim to expand our product range, improve our services, and build long-termpartnerships with customers worldwide.

Our patents and honors

OEM Services

We offer OEM services to provide custom manufacturing solutions tailored to your specifications. This includes:

- Custom designs and specifications

- Prototyping and testing

- Full production capabilities

Frequently Asked Questions (FAQs)

Q: What is the lifespan of a sintered metal fiber felt filter?

A: With proper maintenance and cleaning, these filters can have an extended lifespan, often exceeding traditional filters.

Q: Can I customize the size and shape of the filter?

A: Yes, we offer various customization options to meet your specific needs.

Q: What industries commonly use sintered metal fiber felt filters?

A: They are widely used in petrochemical, pharmaceutical, food and beverage, and gas filtration industries.

Q: How do I clean and maintain the filter?

A: Regular cleaning can be done using suitable solvents or cleaning agents, depending on the application and contaminants.

Contact Details

For more information or to request a quote, please contact us:

- Email: info@mmo-anode.com

- Phone Numbers:

- +86 18395477537

- +86 13759759535

- +86 18991769543

- +86 15891475263

- WhatsApp: +86 18395477537, +86 13759759535, +86 18991769543, +86 15891475263

Send Inquiry