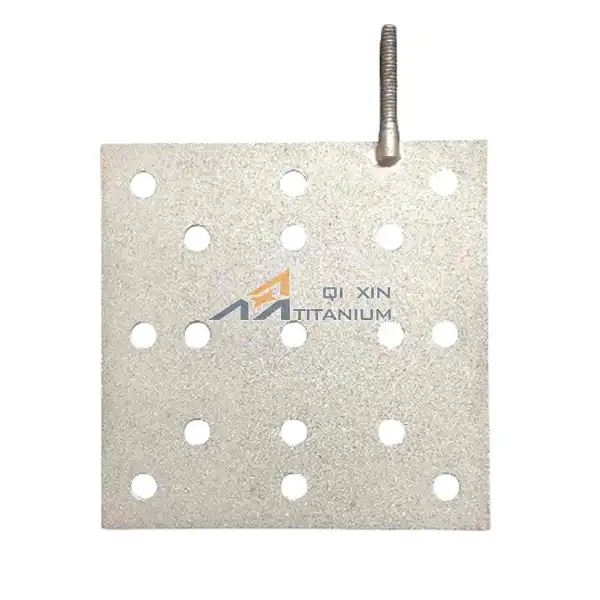

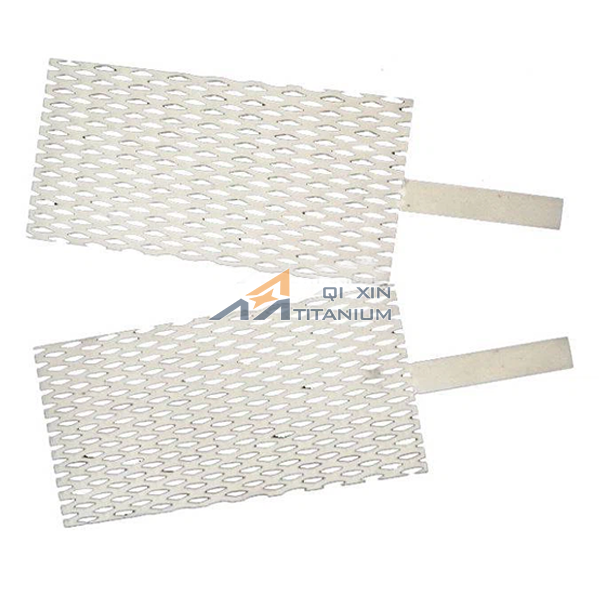

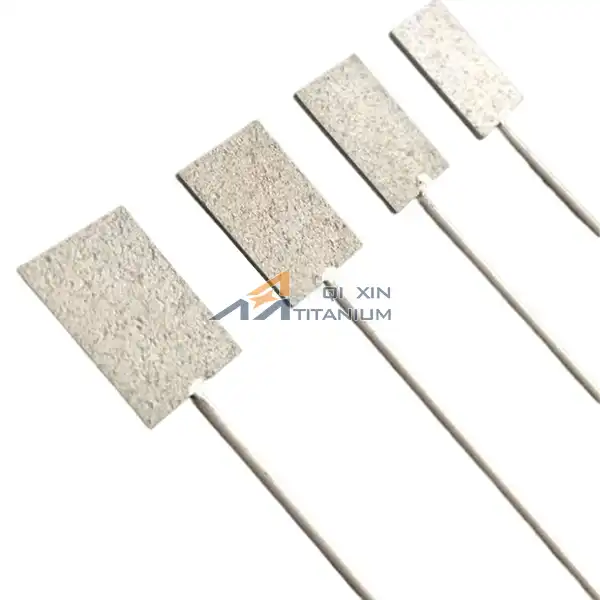

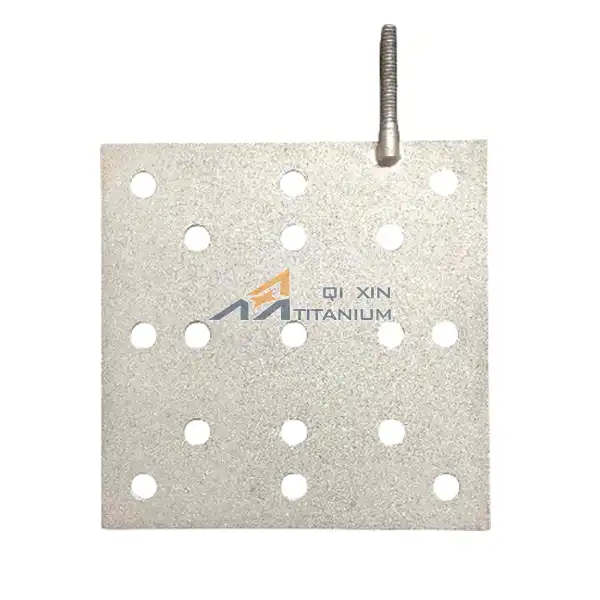

Platinized Titanium Cylinder Electrode

2.Ru-ir oxide Coating,8-12micron;ir-ta oxide coating 8-12micron;platinum coating 0.5-2.5micron.

3.Size: Customizable.

4.Surface Treatment: Sand blasting,Acid cleaning, Polished,brushing.

5.production time: 15 working days.

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Platinized Titanium Cylinder Electrode Introduction

The Platinized Titanium Cylinder Electrode is a sophisticated electrochemical component essential in various applications, including electrolysis, water treatment, and metal plating. These electrodes combine the excellent properties of titanium with a platinum coating, enhancing their performance and durability in demanding environments. This innovative design offers high conductivity and exceptional corrosion resistance, making them ideal for applications that require reliable and long-lasting performance.

Key Features

- Corrosion Resistance: The titanium substrate provides superior resistance to corrosion, ensuring a longer lifespan even in harsh chemical environments.

- Durability: The robust construction and platinum coating enhance the electrode's durability, making it suitable for continuous operation in various applications.

- Electrical Conductivity: High electrical conductivity ensures efficient performance, allowing for improved process efficiency and reduced energy costs.

Technical Specifications

| Specification | Value |

|---|---|

| Material Composition | Titanium substrate with platinized surface |

| Platinum Thickness | 2-10 micrometers (customizable) |

| Dimensions | Custom dimensions available on request |

| Surface Treatment | Anodizing, coating for enhanced performance |

| Max Operating Temperature | Up to 300°C |

| Typical Resistance | < 0.1 ohms per electrode |

| Standard Shapes | Cylindrical, custom shapes available |

|

|

|

|

|

|

|

|

Physical and Chemical Properties

Corrosion Resistance

Platinized titanium electrodes exhibit remarkable resistance to various corrosive environments. The combination of titanium and platinum effectively protects the underlying material, ensuring the electrode's integrity over extended periods.

High Temperature Resistance

These electrodes are designed to perform exceptionally well under high-temperature conditions, making them suitable for applications involving intense heat without compromising their structural integrity.

Product Features

How It Works

In electrochemical processes, the Platinized Titanium Cylinder Electrode acts as a conductive surface where electrolysis occurs. When an electric current is applied, chemical reactions take place on the electrode surface, facilitating processes like metal plating or water purification.

Benefits

- Increased Efficiency: The superior conductivity of these electrodes enhances the efficiency of electrochemical processes, reducing operational costs.

- Longer Service Life: The durable construction ensures a longer lifespan, minimizing the need for frequent replacements and associated costs.

- Reduced Maintenance Costs: Their robust nature leads to fewer maintenance requirements, allowing for uninterrupted operations.

Applications

Industries Served

Platinized Titanium Cylinder Electrodes are widely used across various industries, including:

- Electroplating: Enhancing the surface properties of metals.

- Water Treatment: Facilitating electrochemical processes for purifying water.

- Chemical Processing: Supporting reactions that require stable and efficient electrodes.

|

|

|

|

Case Studies

- Electroplating Plant: A major electroplating facility adopted our electrodes, resulting in a 30% increase in process efficiency and a significant reduction in maintenance costs.

- Desalination Facility: Our electrodes were instrumental in improving the reliability and efficiency of the desalination process, providing a sustainable solution for water purification.

Manufacturing Process

Quality Assurance

At Qixin Titanium Co., Ltd., we implement stringent quality control measures throughout our manufacturing process. This includes thorough testing of raw materials, in-process inspections, and final product evaluations to ensure that each electrode meets the highest standards of quality.

Certifications

Our manufacturing processes comply with ISO 9001 standards, ensuring that our products are consistently produced to meet international quality standards.

Company Overview

Background

Established in 2006, Qixin Titanium Co., Ltd. has nearly two decades of experience in manufacturing coated titanium products. Our commitment to quality and innovation has positioned us as a leader in the industry.

Mission and Vision

We are dedicated to providing high-quality coated titanium anodes and electrodes that meet our clients' diverse needs while fostering innovation and continuous improvement.

Packaging and Logistics

Shipping Information

We employ customized packaging solutions to protect our Platinized Titanium Cylinder Electrodes during transportation. Our packaging is designed to prevent damage and maintain product integrity.

Delivery Times

Typical production and delivery times range from 4 to 6 weeks, depending on the order volume and specifications.

Why Choose Us

Unique Selling Point

Choosing Qixin Titanium Co., Ltd. means partnering with a leader in the coated titanium electrode market. Our extensive experience, commitment to quality, and innovative approach set us apart from the competition.

Recommendation

We have received positive feedback from numerous satisfied customers who have experienced the benefits of our Electrodes, contributing to their operational success.

Factory Show

|

|

|

Equipment

|

|

|

Production

|

|

|

Testing

|

|

Packaging

|

|

|

Our coated titanium anode are widely used in industries such as electrochemistry, water treatment, and metalplating. They are known for their excellent performance, durability, and efficiency, which helps our customersachieve their production goals and enhance their competitiveness in the market.

Quality is our top priority. We adhere to strict quality control measures throughout the manufacturing process toensure that every anode we produce is of the highest quality. Additionally, we offer customized solutions to meetthe specific needs of our clients, providing them with tailor-made products that perfectly fit their applications.At Oixin titanium Co.Ltd, we are committed to providing exceptional customer service. Our dedicated salesand support teams work closely with customers to understand their reauirements and provide prompt andeffective assistance.Looking to the future, we will continue to invest in research and development to stau at the forefront of the coatedtitanium anode industry. We aim to expand our product range, improve our services, and build long-termpartnerships with customers worldwide.

Our patents and honors

OEM Services

Customization Options

We offer tailored manufacturing solutions according to customer specifications, ensuring that our products meet the unique needs of various applications.

FAQs

Common Queries

-

What is the typical lifespan of a Platinized Titanium Cylinder Electrode? The lifespan can vary based on usage and application, but our electrodes are designed for extended durability, often lasting several years under normal conditions.

-

Can I order custom dimensions? Yes, we provide options for custom sizes and specifications to meet specific application requirements.

Contact Details

For more information or to request a quote, please contact us:

- Email: info@mmo-anode.com

- Phone: +86 18395477537, +86 13759759535, +86 18991769543, +86 15891475263

- WhatsApp: +86 18395477537, +86 13759759535, +86 18991769543, +86 15891475263

Send Inquiry

_1732872775739.webp)

_1732872347254.webp)