sintered porous metal filter for food and beverage

Filter Rating:0.5um-50um.

Porosity:30-45%.

Penetrability:3-800M³/M²hKPa.

Working pressure:2.0MPa.

Operating temperature:300℃.

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

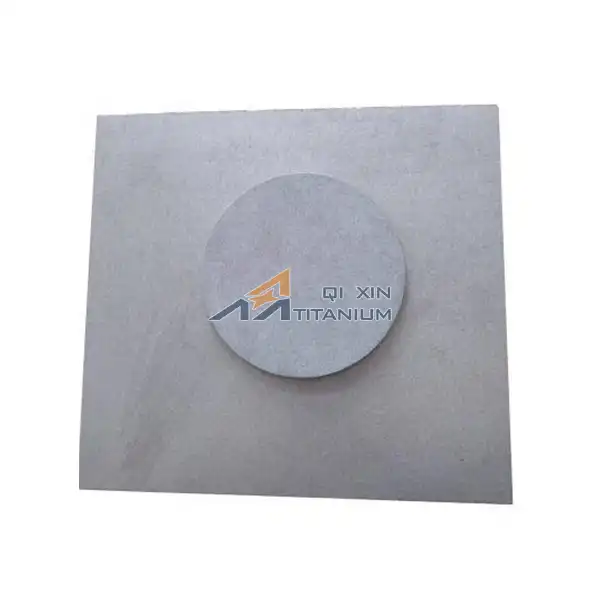

Sintered Porous Metal Filter for Food and Beverage Introduction

The sintered porous metal filter for food and beverage is engineered to perform under extreme conditions, providing robust filtration solutions. This filter is resistant to high temperatures and corrosion, making it ideal for challenging environments like high-pressure and high-temperature applications. Its durable, stable structure ensures consistent, reliable filtration, meeting the exacting standards required in the food and beverage industry.

Technical Specifications

Below is a detailed table of technical specifications for easy reference:

| Specification | Value |

|---|---|

| Material | Stainless Steel, Titanium, Nickel |

| Pore Size Range | 0.5 – 100 microns |

| Filtration Efficiency | Up to 99.9% |

| Operating Temperature | Up to 500°C |

| Operating Pressure | Up to 300 PSI |

| Available Sizes | Customizable to client specifications |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Product Features

- High Porosity: Allows efficient fluid flow and minimizes pressure drop.

- Durability: Designed for long-term use, resisting wear from frequent cleaning and exposure.

- Easy Maintenance: Can be cleaned and reused multiple times, reducing replacement frequency.

- Superior Temperature and Corrosion Resistance: Ideal for harsh processing conditions in food and beverage manufacturing.

Applications

The sintered porous metal filter is versatile across various applications:

- Food and Beverage: Ideal for filtering impurities in beverages, syrups, and oils, ensuring product purity.

- Pharmaceutical: Effective in aseptic filtration where purity and sterility are paramount.

- Gas Filtration: Used in CO₂ and other gas filtration applications in beverage carbonation processes.

These filters excel in precision filtration, separation, and purification tasks, enhancing product quality and safety.

|

|

|

|

Manufacturing Process

Our filters are crafted through a meticulous sintered porous metal filter for food and beverage, which forms a highly durable structure with optimal porosity. This process includes layering metal powders under high heat, resulting in exceptional strength and longevity. Special molding processes and optional multi-layer structures are available for enhanced functionality.

Customization Options

We provide tailored solutions to meet your specific filtration requirements, offering options in:

- Size

- Aperture

- Shape

- Material Selection

Our flexible production capabilities allow us to deliver bespoke filters that integrate seamlessly into your operations.

Quality Assurance

Quality is integral to our production process. We follow rigorous quality control measures, verified through ISO-certified standards, to ensure each filter meets our high-performance benchmarks. Our comprehensive testing and inspection processes guarantee the highest quality products.

Packaging and Logistics

To ensure safe delivery, each filter is packaged to withstand environmental and transit stresses. Our logistics team ensures timely delivery to support continuous operation schedules in food and beverage production facilities.

Customer Support

Our team is dedicated to providing complete customer support from pre-sales to after-sales. We assist with product selection, application guidance, and technical troubleshooting to ensure maximum benefit from our sintered porous metal filter for food and beverage products.

Why Choose Us

With nearly two decades of experience, we stand out in the filtration industry with:

- Extensive Customization: Tailored solutions to fit exact needs.

- Uncompromising Quality: Rigorous quality controls to guarantee top-tier products.

- Timely Delivery: Reliable logistics for uninterrupted supply.

- Dedicated Support: Pre- and post-sale support to maximize customer satisfaction.

Factory Show

|

|

|

Equipment

|

|

|

Production

|

|

|

Testing

|

|

Packaging

|

|

|

Our coated titanium anode are widely used in industries such as electrochemistry, water treatment, and metalplating. They are known for their excellent performance, durability, and efficiency, which helps our customersachieve their production goals and enhance their competitiveness in the market.

Quality is our top priority. We adhere to strict quality control measures throughout the manufacturing process toensure that every anode we produce is of the highest quality. Additionally, we offer customized solutions to meetthe specific needs of our clients, providing them with tailor-made products that perfectly fit their applications.At Oixin titanium Co.Ltd, we are committed to providing exceptional customer service. Our dedicated salesand support teams work closely with customers to understand their reauirements and provide prompt andeffective assistance.Looking to the future, we will continue to invest in research and development to stau at the forefront of the coatedtitanium anode industry. We aim to expand our product range, improve our services, and build long-termpartnerships with customers worldwide.

Our patents and honors

OEM Services

We offer OEM manufacturing solutions, allowing you to integrate custom specifications for unique filtration requirements.

Frequently Asked Questions (FAQs)

-

What materials are available for these filters?

- Options include stainless steel, titanium, and nickel.

-

Can these filters handle high-pressure applications?

- Yes, they are engineered for high-pressure environments, suitable for up to 300 PSI.

-

How do I clean and maintain these sintered porous metal filter for food and beverage?

- They are designed for easy cleaning and reuse, allowing for prolonged use without frequent replacement.

Contact Details

For inquiries, quotes, or additional information, contact us at:

- Email: info@mmo-anode.com

- Phone: 8618395477537, 8613759759535, 8618991769543, 8615891475263

- WhatsApp: 8618395477537, 8613759759535, 8618991769543, 8615891475263

Reach out today to discuss how our sintered porous metal filters can elevate your production processes.

Send Inquiry