titanium anode baskets

The common mesh size are like the following:

6mm × 3mm、10mm × 3mm、10mm × 5mm etc. Titanium basket has high strength, light weight, corrosion resistance and a layer of oxide film on the surface.

Under normal electroplating conditions, this film can prevent the current from passing through the titanium baskets and make the current directly lead to the anode material inside if the basket.

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Titanium Anode Baskets Introduction

Welcome to the premier destination for titanium anode baskets, expertly crafted by Baoji Qixin Titanium Co., Ltd. With over 18 years of manufacturing excellence, we specialize in producing high-quality coated titanium anodes that cater to a wide range of industries, including electrochemistry, water treatment, and metal plating. Our commitment to quality and innovation ensures that our products not only meet but exceed the highest standards in performance and durability.

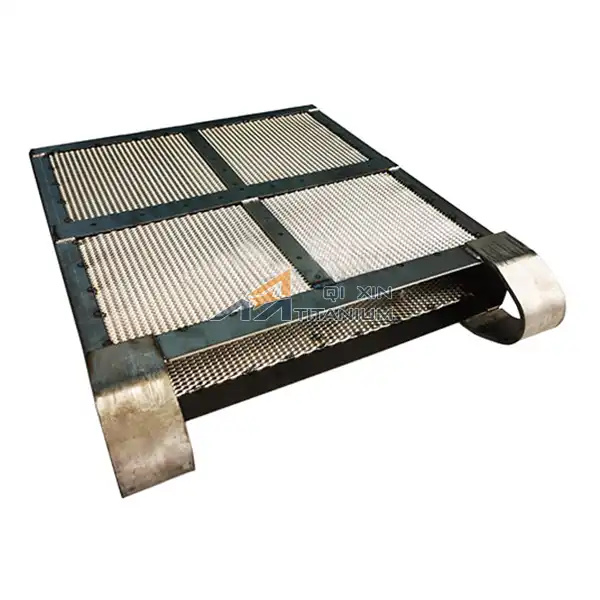

Titanium Electroplating Rack

A titanium electroplating rack serves a vital role in the electroplating process. It carries and securely holds electroplated parts, ensuring uniform coverage and efficient operations. Made from premium materials, these racks enhance the electroplating experience, ensuring that each piece receives consistent treatment.

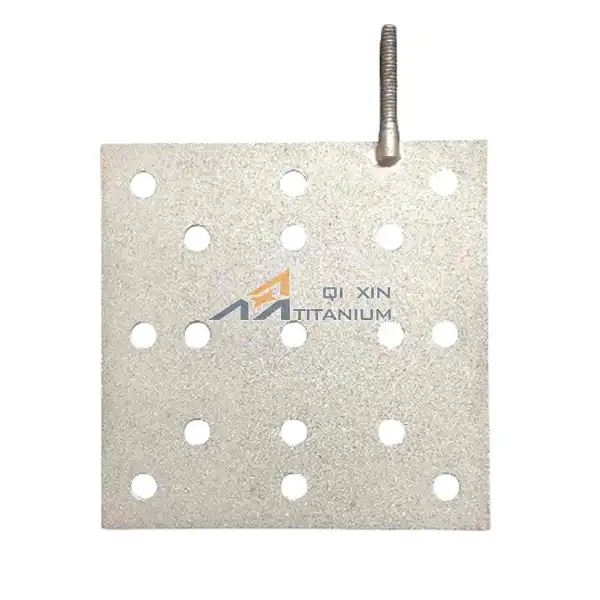

Titanium Anode Basket

Our products are specifically designed as anode supports in electrolysis and electroplating processes. They can be filled with electroplating materials, allowing for a uniform electrolysis effect. With their robust construction and resistance to harsh conditions, these baskets play a critical role in optimizing electroplating outcomes.

Technical Specifications

Titanium Electroplating Rack

| Feature | Specification |

|---|---|

| Material | Pure Titanium or Titanium Alloy |

| Dimensions | Customizable per client needs |

| Weight | Varies based on dimensions |

| Load Capacity | Up to 200 kg |

| Surface Treatment | Anodized for enhanced durability |

Titanium Anode Basket

| Feature | Specification |

|---|---|

| Basket Size | Customizable (e.g., 300mm x 200mm) |

| Mesh Size | 0.5mm to 2mm |

| Capacity | Up to 10 kg |

| Applicable Materials | Titanium, Ruthenium Titanium, Iridium Titanium |

Key Features

Titanium Electroplating Rack

- Corrosion Resistance: Ensures longevity even in aggressive environments.

- High Temperature Resistance: Maintains structural integrity under extreme heat.

- Lightweight Design: Easy handling and installation, reducing overall operational costs.

Titanium Anode Basket

- Strong Acid and Alkali Resistance: Withstands the rigors of harsh electrolytic environments.

- Non-Deforming: Engineered to maintain shape and performance over time.

- Excellent Conductivity: Enhances the efficiency of electrolysis, optimizing production.

Titanium Anode Baskets Applications

Titanium Electroplating Rack

Our racks are ideal for the electroplating of various components, including automotive parts, circuit boards, and electronic devices. They ensure efficient and uniform electroplating, crucial for high-quality outputs.

Titanium Anode Basket

These baskets are widely utilized in electroplating and electrolysis processes, particularly for plating metals such as zinc, nickel, and copper. Their robust construction makes them suitable for any demanding electrolysis application.

Manufacturing Process

Titanium Electroplating Rack

Our manufacturing process includes precise welding, shaping, and surface treatment to ensure that each rack is durable and smooth. This attention to detail guarantees long-term stability and reduced maintenance requirements.

Titanium Anode Basket

The production of our anode baskets involves precision welding and sealing treatments, complemented by surface passivation. This ensures strength, resilience, and extended usability, even in challenging conditions.

Customization Options

Titanium Electroplating Rack

We offer customization for size, shape, and structural design to align with specific electroplating processes and client requirements.

Titanium Anode Basket

Our baskets can be customized in terms of mesh density, dimensions, and specialized coatings to accommodate various electrolytic cell configurations.

Quality Assurance

At Qixin Titanium Co., Ltd., we prioritize quality. Our rigorous quality control system ensures the consistency and stability of every product. We proudly adhere to ISO certifications and continuously strive for excellence in our manufacturing processes.

Packaging and Logistics

Both our titanium electroplating racks and titanium anode baskets are packaged securely to prevent damage during transit. We understand the importance of timely delivery and strive to meet our customers' expectations with efficient logistics solutions.

Customer Support

We believe in providing comprehensive support throughout the customer journey. From pre-sales consultations to installation guidance and after-sales maintenance suggestions, our dedicated team ensures that you feel confident in your purchase and its application.

Why Choose Us?

Choosing Baoji Qixin Titanium Co., Ltd. means partnering with an industry leader dedicated to quality, innovation, and customer satisfaction. With our extensive experience and advanced manufacturing techniques, we deliver products that enhance operational efficiency and bolster your competitive edge.

Factory Show

|

|

|

Equipment

|

|

|

Production

|

|

|

Testing

|

|

Packaging

|

|

|

Our coated titanium anode are widely used in industries such as electrochemistry, water treatment, and metalplating. They are known for their excellent performance, durability, and efficiency, which helps our customersachieve their production goals and enhance their competitiveness in the market.

Quality is our top priority. We adhere to strict quality control measures throughout the manufacturing process toensure that every anode we produce is of the highest quality. Additionally, we offer customized solutions to meetthe specific needs of our clients, providing them with tailor-made products that perfectly fit their applications.At Oixin titanium Co.Ltd, we are committed to providing exceptional customer service. Our dedicated salesand support teams work closely with customers to understand their reauirements and provide prompt andeffective assistance.Looking to the future, we will continue to invest in research and development to stau at the forefront of the coatedtitanium anode industry. We aim to expand our product range, improve our services, and build long-termpartnerships with customers worldwide.

Our patents and honors

Contact Us

For further inquiries or to discuss your specific needs regarding the product, please reach out to us at [info@mmo-anode.com]. We're here to help you optimize your electroplating processes with our high-quality products!

Send Inquiry