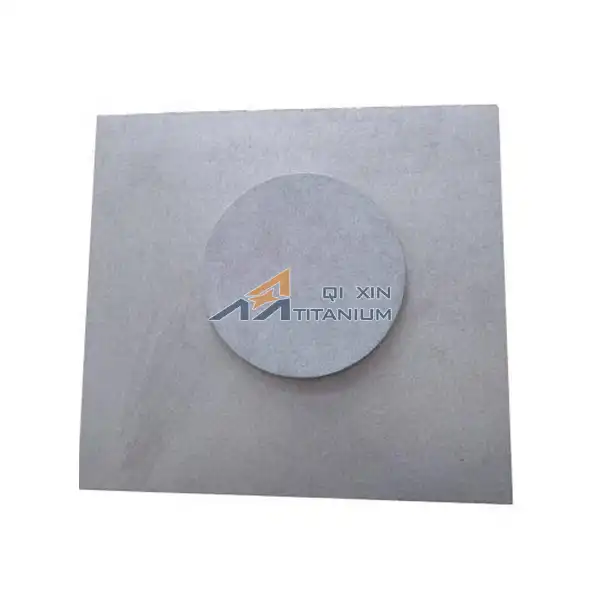

sintered metal disc filter

Filter Rating:0.5um-50um.

Porosity:30-45%.

Penetrability:3-800M³/M²hKPa.

Working pressure:2.0MPa.

Operating temperature:300℃.

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Sintered Metal Disc Filter Introduction

Our Sintered Metal Disc Filters offer exceptional durability, high-temperature resistance, and corrosion resistance, making them ideal for extreme conditions such as high-pressure and high-temperature environments. These filters maintain structural integrity and are reliable for fine filtration, separation, and purification processes.

Technical Specifications

| Parameter | Specification |

|---|---|

| Material Options | Stainless Steel, Titanium, Nickel |

| Pore Size Range | 0.2 – 100 microns |

| Filtration Efficiency | Up to 99.9% |

| Operating Temperature | -200°C to +1000°C |

| Operating Pressure | Up to 10 MPa |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Key Features

- High Porosity: Allows excellent flow rates and reduced energy costs.

- Durability: Withstands high temperatures, corrosion, and pressure.

- Reusable and Easy to Clean: Minimal maintenance required.

- Versatile Applications: Adaptable to various industrial settings.

Applications

Our sintered metal disc filters are utilized in diverse fields:

- Petrochemical Industry: Effective in removing contaminants from fuels and chemicals.

- Pharmaceuticals: Ensures high purity levels in medicines and other formulations.

- Food & Beverage: Purifies liquids and gases, meeting food safety standards.

- Gas Filtration: Enhances air and gas purity in industrial applications.

|

|

|

|

Manufacturing Process

The filters are manufactured through a sintering process, which involves heating powdered metal under pressure to create a solid structure. This unique process results in high strength, structural stability, and consistent pore size distribution, providing an efficient, long-lasting filtration solution.

Customization Options

We offer extensive customization options, including size, pore size, shape, and material choice. Our flexible production capabilities allow us to tailor the product to fit your exact specifications, making our filters ideal for any specialized application.

Quality Assurance

Our filter's Quality Assurance ensures that every product meets the highest standards of durability and performance. Through rigorous testing and inspection processes, we verify that each filter is free from defects and operates efficiently under various conditions. Our commitment to quality is reflected in the use of advanced materials and precise manufacturing techniques, guaranteeing reliable filtration solutions for our customers. With continuous improvements, we strive to exceed industry expectations and deliver exceptional products.

Packaging and Logistics

Our filter's Customer Support provides comprehensive assistance to ensure optimal performance and longevity of your filtration systems. Our team of experts is available to address any inquiries or technical issues, offering solutions ranging from installation guidance to routine maintenance tips. With a focus on customer satisfaction, we ensure that our clients receive timely and efficient support to maximize the reliability and efficiency of their filters.

Customer Support

Our team is committed to providing exceptional support before and after your purchase. For any questions, troubleshooting, or technical guidance, contact us at info@mmo-anode.com.

Why Choose Us?

- 18+ Years of Expertise: Trusted in the industry since 2006.

- Advanced Engineering: Cutting-edge manufacturing for reliable and efficient products.

- Tailored Solutions: Customization to meet diverse industry needs.

- Quality Commitment: ISO-certified with rigorous testing for quality assurance.

- Customer-Centric: Dedicated to outstanding support and customer satisfaction.

Factory Show

|

|

|

Equipment

|

|

|

Production

|

|

|

Testing

|

|

Packaging

|

|

|

Our coated titanium anode are widely used in industries such as electrochemistry, water treatment, and metalplating. They are known for their excellent performance, durability, and efficiency, which helps our customersachieve their production goals and enhance their competitiveness in the market.

Quality is our top priority. We adhere to strict quality control measures throughout the manufacturing process toensure that every anode we produce is of the highest quality. Additionally, we offer customized solutions to meetthe specific needs of our clients, providing them with tailor-made products that perfectly fit their applications.At Oixin titanium Co.Ltd, we are committed to providing exceptional customer service. Our dedicated salesand support teams work closely with customers to understand their reauirements and provide prompt andeffective assistance.Looking to the future, we will continue to invest in research and development to stau at the forefront of the coatedtitanium anode industry. We aim to expand our product range, improve our services, and build long-termpartnerships with customers worldwide.

Our patents and honors

OEM Services

Our team offers OEM solutions for custom manufacturing according to client specifications. Let us help bring your specialized designs to life with our high-performance filtration solutions.

Frequently Asked Questions (FAQs)

-

What is the pore size range for sintered metal disc filter?

Our filters are available in a pore size range of 0.2 – 100 microns. -

Can the filters withstand high temperatures?

Yes, they operate effectively between -200°C and +1000°C, depending on the material. -

Do you offer customized filter sizes?

Absolutely. We can customize the size, pore size, shape, and materials to suit your specific needs.

Contact Details

For further information about the Sintered Metal Disc Filter, please feel free to contact us at info@mmo-anode.com. With Qixin Titanium Co., Ltd., you receive not just a product but a partnership dedicated to quality, performance, and innovation.

Send Inquiry