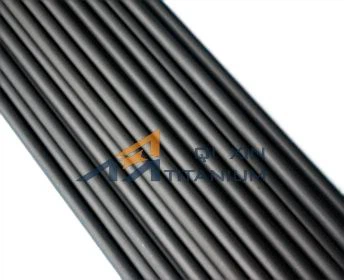

Titanium Rack for Electroplating

Diameter: dia220mm, 250mm, 270mm.

Teeth: 30 teeth 25 teeth 20 teeth 15 teeth 42 teeth 50 teeth.

Titanium plate normal thickness: 1.0mm 1.2mm.

Surface: Polished.

Application: Electroplating, anodizing etc.

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Titanium Rack for Electroplating Product Introduction

In the world of electroplating, precision and efficiency are paramount. The Titanium Rack for Electroplating plays a crucial role in this process by securely carrying and fixing electroplated parts. Designed to ensure uniformity and optimize the electroplating experience, this specialized rack is crafted from high-quality titanium, offering durability and resistance to corrosion. Whether you are in the automotive, electronics, or metal plating industry, our titanium racks help you achieve consistent and high-quality finishes.

The Titanium Anode Basket, on the other hand, serves as an essential anode support in electrolysis and electroplating processes. This basket can be filled with various electroplating materials, ensuring a uniform electrolysis effect. With its robust design and adaptability, it is perfect for a wide range of applications, making it an invaluable component for industries looking to enhance their electroplating capabilities.

Technical Specifications

| Product | Dimension (mm) | Weight (kg) | Load Capacity (kg) | Material Specifications |

|---|---|---|---|---|

| Titanium Electroplating Rack | 600 x 400 x 200 | 4 | 50 | Pure Titanium or Titanium Alloy |

| Titanium Anode Basket | 300 x 200 x 150 | 2 | 30 | Titanium, Ruthenium Titanium, Iridium Titanium |

Key Features

Titanium Electroplating Rack

- Corrosion Resistance: Designed to withstand harsh electroplating environments, ensuring longevity and reliability.

- High-Temperature Resistance: Capable of maintaining structural integrity under high temperatures.

- Lightweight: Easy to handle and install, minimizing labor costs and maximizing operational efficiency.

- Low Maintenance Costs: Durable construction requires less frequent replacement, leading to overall cost savings.

Titanium Anode Basket

- Strong Acid and Alkali Resistance: Perfect for demanding electrolysis environments where chemical stability is critical.

- Deformation Resistant: Engineered to retain its shape even under stress, providing consistent performance.

- Good Conductivity: Facilitates efficient electrolysis, ensuring effective plating results while reducing waste of electroplating solution.

Titanium Rack for Electroplating Applications

Titanium Electroplating Rack

Ideal for various electroplating processes, the titanium rack is particularly effective in:

- Automotive Parts: Ensuring uniform coating on intricate shapes and designs.

- Circuit Boards: Supporting delicate components while maintaining electroplating integrity.

- Electronic Components: Facilitating efficient operation and consistent finishes across multiple items.

Titanium Anode Basket

Widely utilized in industries that require efficient electroplating and electrolysis processes, suitable for:

- Zinc, Nickel, and Copper Electroplating: Providing robust support for various metal plating processes.

- Electrolysis Processes: Essential for operations needing high corrosion resistance and durability.

Manufacturing Process

Titanium Electroplating Rack

The production of our titanium electroplating racks involves:

- Welding: Precision welding techniques ensure structural integrity.

- Forming: Expertly shaped to meet specific operational needs.

- Surface Treatment: Advanced finishing processes provide smooth surfaces, enhancing electroplating efficiency.

Titanium Anode Basket

Our titanium anode baskets are crafted through:

- Precision Welding: To ensure robust joints that withstand operational demands.

- Solder Joint Sealing Treatment: Enhancing the durability of joints against corrosion.

- Surface Passivation: Protecting the basket against wear and extending its lifespan.

Customization Options

Titanium Electroplating Rack

We understand that every Titanium Rack for Electroplating is unique. Therefore, we offer customization for:

- Size and Shape: Tailored to fit specific parts and processes.

- Structural Design: Adjustments to meet operational requirements effectively.

Titanium Anode Basket

Customization is also available for our anode baskets, including:

- Basket Mesh Density: Options to fit different electrolysis setups.

- Size and Special Coatings: Adapted to various electrolytic cell configurations for optimal performance.

Quality Assurance

At Baoji Qixin Titanium Co., Ltd., quality is our utmost priority. We implement a rigorous quality control system to ensure that every product meets the highest standards. Our facilities are ISO certified, reflecting our commitment to excellence and consistency in every titanium rack and anode basket we produce.

Packaging and Logistics

Both our titanium plating racks and anode baskets are packaged to ensure safety during transportation. We use protective materials that shield our products from damage and environmental factors. Our efficient logistics systems guarantee timely delivery, ensuring that your operations are never delayed.

Customer Support

We pride ourselves on providing comprehensive support services, including:

- Pre-sales Consultation: Helping you choose the right products for your needs.

- Installation Guidance: Ensuring that you can effectively use our products.

- After-sales Maintenance Suggestions: Offering insights to help you maximize product benefits and longevity.

Why Choose Us

Choosing Baoji Qixin Titanium Co., Ltd. means partnering with a leader in the coated titanium anode industry. With nearly two decades of experience, our high-quality production techniques, stringent quality control measures, and commitment to customer satisfaction make us the preferred choice for businesses in various sectors. We provide tailored solutions that enhance your operational efficiency, backed by unparalleled customer support.

Factory Show

|

|

|

Equipment

|

|

|

Production

|

|

|

Testing

|

|

Packaging

|

|

|

Our coated titanium anode are widely used in industries such as electrochemistry, water treatment, and metalplating. They are known for their excellent performance, durability, and efficiency, which helps our customersachieve their production goals and enhance their competitiveness in the market.

Quality is our top priority. We adhere to strict quality control measures throughout the manufacturing process toensure that every anode we produce is of the highest quality. Additionally, we offer customized solutions to meetthe specific needs of our clients, providing them with tailor-made products that perfectly fit their applications.At Oixin titanium Co.Ltd, we are committed to providing exceptional customer service. Our dedicated salesand support teams work closely with customers to understand their reauirements and provide prompt andeffective assistance.Looking to the future, we will continue to invest in research and development to stau at the forefront of the coatedtitanium anode industry. We aim to expand our product range, improve our services, and build long-termpartnerships with customers worldwide.

Our patents and honors

Conclusion

Investing in our Titanium Rack for Electroplating and Titanium Anode Basket means choosing reliability, efficiency, and performance. At Baoji Qixin Titanium Co., Ltd., we are dedicated to helping you achieve your electroplating goals with high-quality products designed for excellence. For more information or to discuss your specific needs, please contact us at [info@mmo-anode.com].

Send Inquiry

You may like

_1732872347254.webp)

_1732863373170.webp)

_1732863107353.webp)