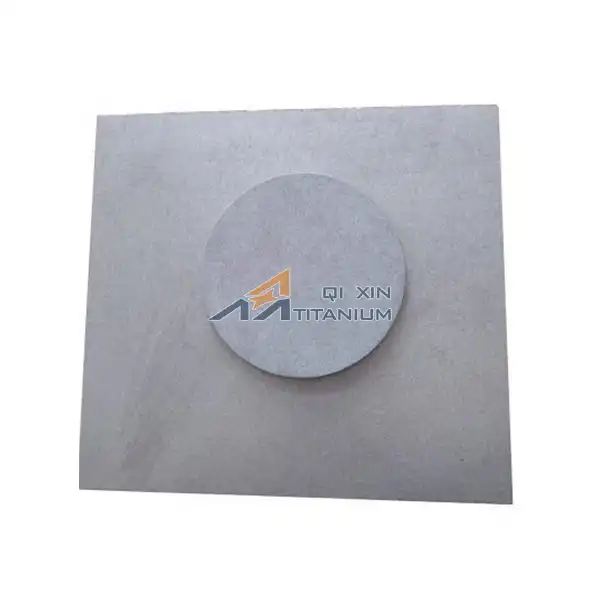

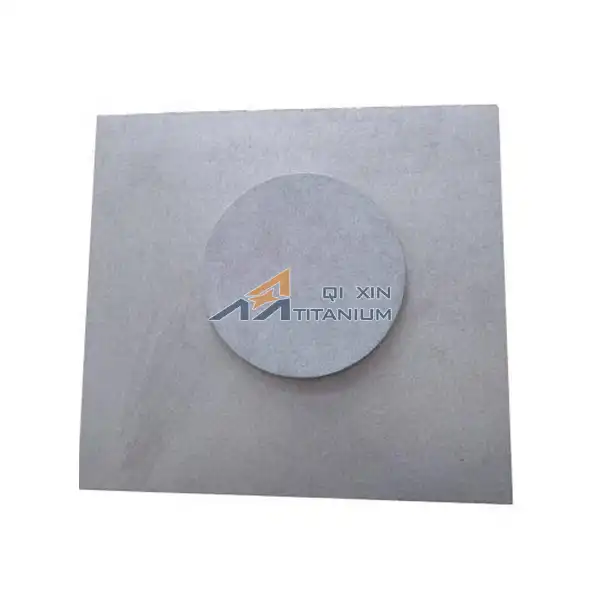

sintered metal filter plate

Filter Rating:0.5um-50um.

Porosity:30-45%.

Penetrability:3-800M³/M²hKPa.

Working pressure:2.0MPa.

Operating temperature:300℃.

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Sintered Metal Filter Plate Introduction

- Sintered metal filter plate from Baoji Qixin Titanium Co., Ltd. are engineered for exceptional durability, high-temperature resistance, and superior structural stability, making them perfect for use in demanding environments such as high-pressure, high-temperature, and corrosive conditions. Utilizing advanced sintering technology, these filters deliver precise filtration, efficient separation, and reliable purification across a wide range of industrial applications.

- Whether in chemical processing, petrochemical industries, or power generation, our sintered metal filters offer optimal performance by withstanding harsh conditions while maintaining high filtration efficiency. Designed for long-term reliability, they minimize downtime, enhance system performance, and provide cost-effective solutions for industrial filtration needs.

Technical Specifications

- Table Format: Provides clarity and quick reference for users.

| Parameter | Details |

|---|---|

| Materials | Stainless steel, titanium, nickel |

| Pore Size Range | 1-200 microns |

| Filtration Efficiency | 99.5% for specific applications |

| Operating Temperature | Up to 900°C |

| Operating Pressure | Up to 10 MPa |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sintered Metal Filter Plate Features

- High Porosity: Facilitates efficient filtration and gas flow.

- Durability and Reusability: Resistant to high temperatures, corrosion, and mechanical stress, offering long service life.

- Ease of Cleaning: Designed for easy maintenance, these plates are reusable with minimal degradation over time.

Sintered Metal Filter Plate Applications

- Petrochemical: Ideal for separation and purification in high-pressure environments.

- Pharmaceutical: Ensures fine filtration for production safety and compliance.

- Food and Beverage: Provides contamination-free filtration, essential in sensitive production lines.

- Gas Filtration: Reliable for precise filtration in various industrial gas applications.

|

|

|

|

Manufacturing Process

- Sintering and Forming: Using advanced multi-layer sintering processes, our filter plates achieve excellent strength and consistent pore distribution, ensuring high mechanical stability and uniform filtration.

Customization Options

- Custom Sizes and Apertures: Available to meet specific filtration needs.

- Material Choices: Customizable materials, including titanium, stainless steel, and nickel, for specialized applications.

- Shape Flexibility: Custom shapes and dimensions based on client requirements, supported by our flexible production capabilities.

Quality Assurance

- ISO Certification: Each filter plate adheres to stringent quality control standards, certified by ISO.

- Rigorous Testing: Every product undergoes multiple stages of inspection, ensuring optimal performance and consistency.

Packaging and Logistics

- Secure Packaging: Customized, protective packaging to avoid damage during transit.

- Efficient Logistics: Rapid delivery timelines and reliable shipping partners ensure timely product delivery worldwide.

Customer Support

- Pre- and Post-Sales Support: Our knowledgeable support team is available to guide customers on optimal product use and maintenance.

- Contact Information: Dedicated customer service channels to address inquiries and provide assistance promptly.

Why Choose Us

- Extensive Experience: Over 18 years of expertise in high-performance, sintered metal filtration solutions.

- Customization Excellence: Tailored solutions to meet specific customer needs across industries.

- Commitment to Quality: ISO-certified processes and dedicated quality control team.

- Technical Support and Timely Delivery: Reliable pre- and post-sales service, with a focus on building lasting partnerships.

Factory Show

|

|

|

Equipment

|

|

|

Production

|

|

|

Testing

|

|

Packaging

|

|

|

Our coated titanium anode are widely used in industries such as electrochemistry, water treatment, and metalplating. They are known for their excellent performance, durability, and efficiency, which helps our customersachieve their production goals and enhance their competitiveness in the market.

Quality is our top priority. We adhere to strict quality control measures throughout the manufacturing process toensure that every anode we produce is of the highest quality. Additionally, we offer customized solutions to meetthe specific needs of our clients, providing them with tailor-made products that perfectly fit their applications.At Oixin titanium Co.Ltd, we are committed to providing exceptional customer service. Our dedicated salesand support teams work closely with customers to understand their reauirements and provide prompt andeffective assistance.Looking to the future, we will continue to invest in research and development to stau at the forefront of the coatedtitanium anode industry. We aim to expand our product range, improve our services, and build long-termpartnerships with customers worldwide.

Our patents and honors

OEM Services

At Baoji Qixin Titanium Co., Ltd., we specialize in providing customized manufacturing solutions to meet the specific requirements of each client. Our sintered metal filter plate can be tailored to unique specifications, including size, shape, pore structure, and material composition, ensuring optimal performance in diverse industrial environments. Whether you require filters for specialized filtration processes, high-temperature resistance, or specific corrosion resistance properties, we work closely with you to design and produce filters that perfectly align with your application needs. Our expert team uses advanced technology to deliver precise, high-quality products that meet both performance and durability standards, guaranteeing customer satisfaction.

Frequently Asked Questions (FAQs)

- Q1: What industries can benefit from using sintered metal filter plate?

- Q2: What are the cleaning methods for these filter plates?

- Q3: Can I customize the pore size or material?

Contact Details

- Direct Contact: Email: info@mmo-anode.com

- Phone and WhatsApp: +86-183-9547-7537, +86-137-5975-9535, +86-189-9176-9543, +86-158-9147-5263

Send Inquiry